About us

We offer endless possibilities to help you accomplish your goals. With the support of our industry experts, your brilliant ideas will never be compromised.

Our Story

LangFuture Company, founded in 2014. We have established a well-established milling cutter processing plant in Jiangsu, China, with several specialised production workshops, where we can trust the quality of our products.

We currently have a global presence. We are confident in our business and we are constantly striving for perfection.

Comparison experiments with big brands in the market, analysis and comparison in material, processing and coating convenience, to provide customers with products with high processing finish and long service life.

Customized

Service

Customer Inquiries

We work closely with you through professional consulting

Client Confirmation

You can check the quality of the product once it has been produced

Product Production

Production experts provide expert insight and advice on every aspect of your idea

Quality Inspection

Our state-of-the-art equipment ensures the production quality of your bespoke tools.

Customer Quotes

We can find a design that achieves your goals within your budget

Delivery Orders

Your completed order will be shipped to you through a trusted logistics

Our

Factory

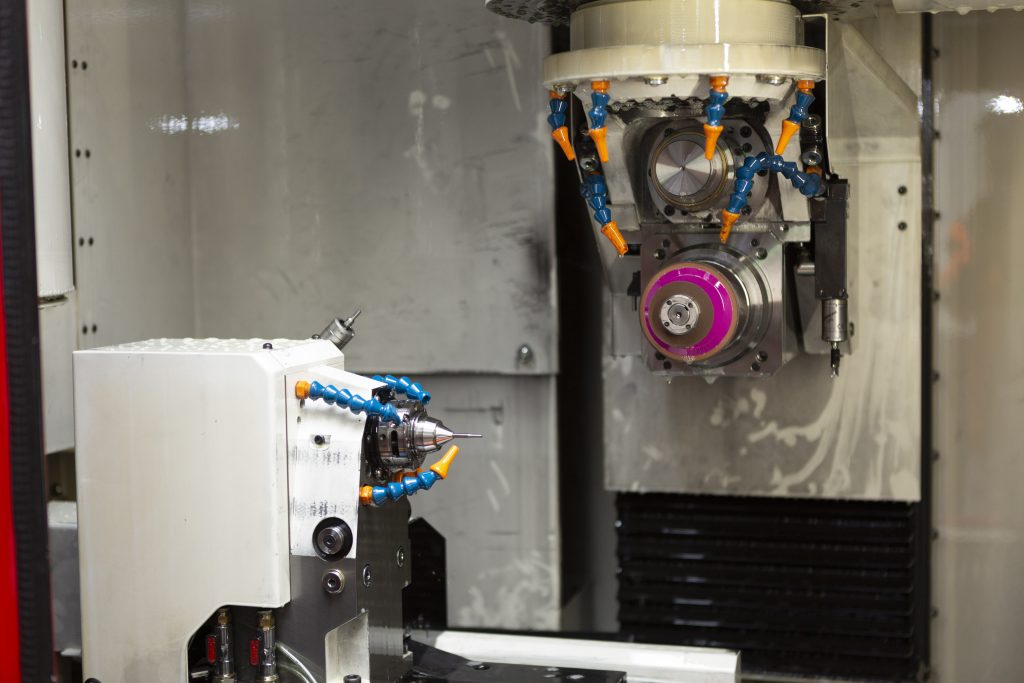

We have domestic advanced production equipment, we are the leader in the milling cutter industry

Product Quality Testing

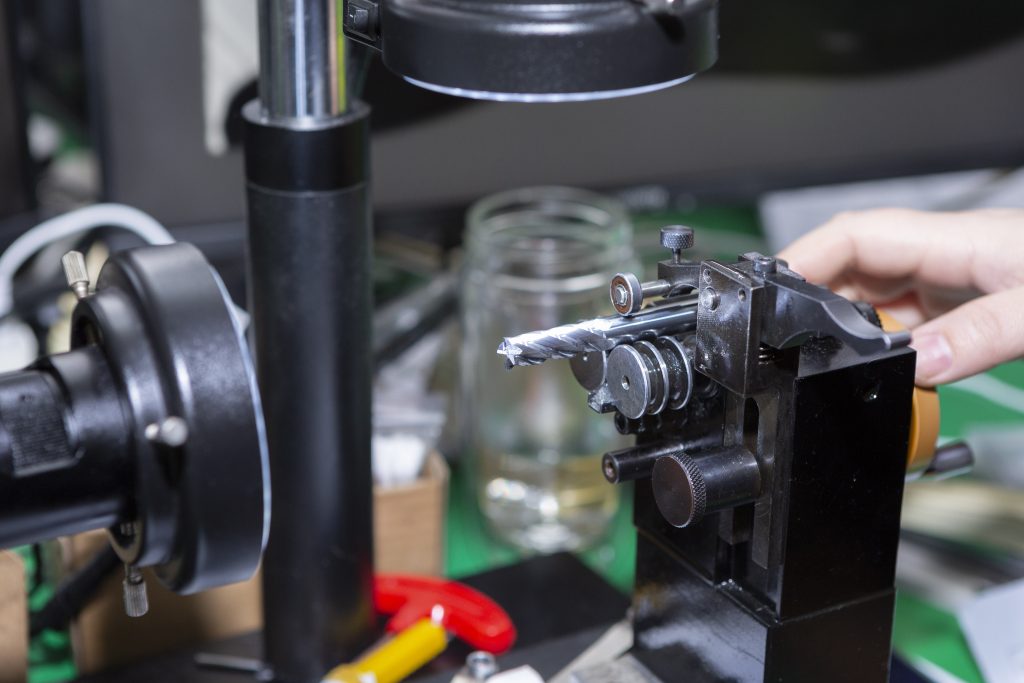

After wire cutting, use calipers to check the length of the bar.

After centreless grinding, measure the outside diameter of the round bar with a micrometer. After top grinding, check the outside diameter of each step of the round bar with a micrometer and measure the length of each step with a PG1000 tool tester.

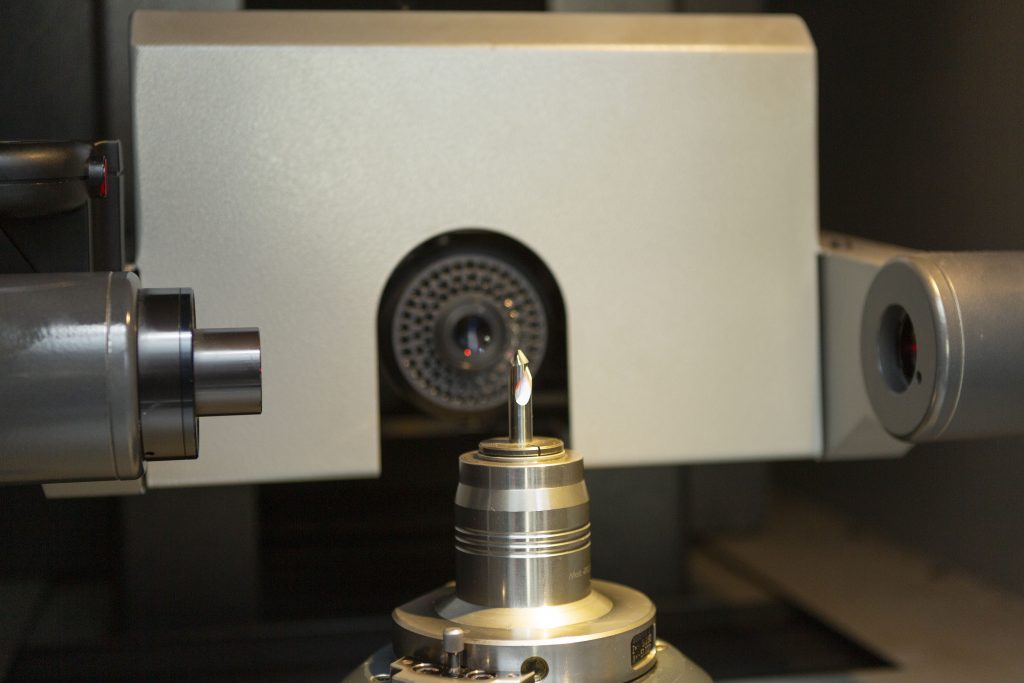

After machining on the 5-axis grinder, the tool is checked with a PG1000 tool tester for front angle, back angle, helix angle, core thickness and other parameter dimensions, as well as appearance. The outside diameter, length, angle and profile are checked with a ZOLLER tool setting instrument.

After external coating, the coating condition and appearance are checked with an industrial microscope or PG1000 tool tester.

Customer Experiences

“Through cooperation, Langming in product quality, duration, cost and other aspects of effective control left us a professional, cost-effective, efficient and good impression. ”

Jennifer W.

Insurance Broker

“We received the first order of end mill here. Those are in good condition & Cutting area is covered with a protective cover to prevent damage. That is very good.”

Jennifer W.

Insurance Broker

“We have already tested a 10 mm end for Stainless steel with good yield & Test going on for a 3 mm end mill for an aluminum one. i have confidence that it will bring a good result.”

Jennifer W.

Insurance Broker

“I have been in the industry for over ten years and LANGFANG Tools is a great partner to work with. I am satisfied with the quality of their products.”

Jennifer W.

Insurance Broker

Our Advanced

Equipments

Don't be shy, Get all you want!

Contact us for a quick catalogue and quote. We have a feeling that this is the beginning of a professional friendship.